Innovating Production Processes Globally

In an increasingly interconnected global economy, the way goods are produced and delivered is undergoing continuous transformation. Businesses worldwide are recognizing the imperative to evolve their production processes, not merely to keep pace with change but to drive it. This evolution encompasses a broad spectrum of advancements, from the integration of cutting-edge technology to the strategic restructuring of supply chains, all aimed at enhancing efficiency, fostering resilience, and unlocking new avenues for growth across diverse markets.

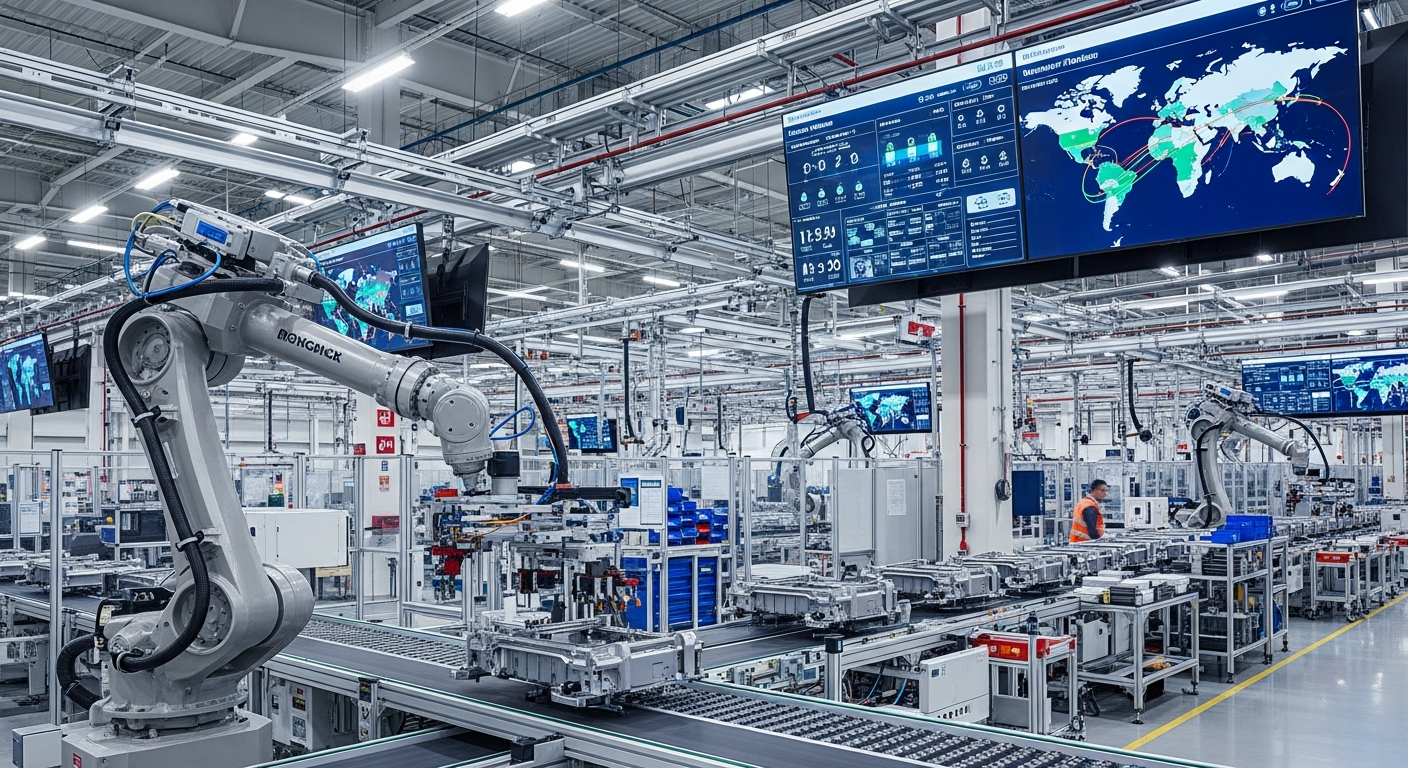

How Technology and Automation Drive Modern Manufacturing?

Modern manufacturing is fundamentally reshaped by advancements in technology and automation. The adoption of Industry 4.0 principles, which include the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics, is revolutionizing production floors. These technologies enable smart factories where machines communicate, data is collected in real-time, and processes are optimized autonomously. This integration enhances precision, accelerates production cycles, and significantly improves quality control across various manufacturing operations. Automation not only reduces human error but also allows for more complex and customized production, meeting the diverse demands of global markets with greater agility.

Navigating Global Supply Chains and Market Dynamics

The intricate web of global supply chains presents both opportunities and challenges for enterprises. Innovating production processes globally often means rethinking how raw materials are sourced, how goods are transported, and how finished products reach consumers across different regions. Effective logistics and supply chain management are crucial for maintaining a competitive edge. This involves diversifying supplier networks, implementing robust risk management strategies, and leveraging predictive analytics to anticipate market shifts and potential disruptions. Businesses must adapt their operations to regional trade policies, economic fluctuations, and consumer preferences to ensure seamless flow and sustained trade.

Enhancing Operational Efficiency and Sustainable Growth

Efficiency is a cornerstone of innovative production processes. Companies are continuously exploring methods to streamline operations, reduce waste, and optimize resource utilization. Lean manufacturing principles, continuous improvement methodologies, and Six Sigma practices are widely adopted to identify bottlenecks and enhance productivity. Beyond immediate gains, there is a growing emphasis on sustainable development. This includes adopting eco-friendly production techniques, minimizing carbon footprints, and ensuring ethical sourcing. Such practices not only contribute to environmental stewardship but also enhance brand reputation and appeal to a growing segment of environmentally conscious consumers, driving long-term growth.

Building a Resilient Workforce and Strategic Enterprise

The human element remains critical in the context of advanced production. An innovative enterprise fosters a resilient workforce capable of adapting to new technologies and evolving operational demands. Investment in upskilling and reskilling programs is essential to equip employees with the necessary expertise for automation, data analysis, and advanced manufacturing techniques. Strategically, businesses must develop robust frameworks for risk assessment and mitigation, preparing for unforeseen challenges such as economic downturns or global events. This strategic foresight ensures business continuity and protects the integrity of production and supply networks, bolstering overall organizational resilience.

The Role of Data in Driving Innovation and Economy

Data has emerged as a vital asset in driving innovation and influencing the broader economy. In production, the collection and analysis of big data from various sources—including factory floor sensors, supply chain logistics, and market feedback—provide invaluable insights. These insights enable predictive maintenance, optimize inventory levels, and inform product development. Leveraging data analytics allows companies to identify trends, forecast demand more accurately, and make informed strategic decisions that foster innovation. This data-driven approach contributes significantly to economic development by enhancing productivity, creating new business models, and improving resource allocation across industries.

Innovating production processes globally is a continuous journey that requires a holistic approach, integrating technological advancements with strategic planning, operational excellence, and a focus on human capital. Companies that successfully navigate this complex landscape are better positioned to achieve sustained growth, adapt to market changes, and contribute positively to the global economy. The ongoing evolution in manufacturing and enterprise operations underscores the importance of agility, foresight, and a commitment to continuous improvement in an ever-changing world.